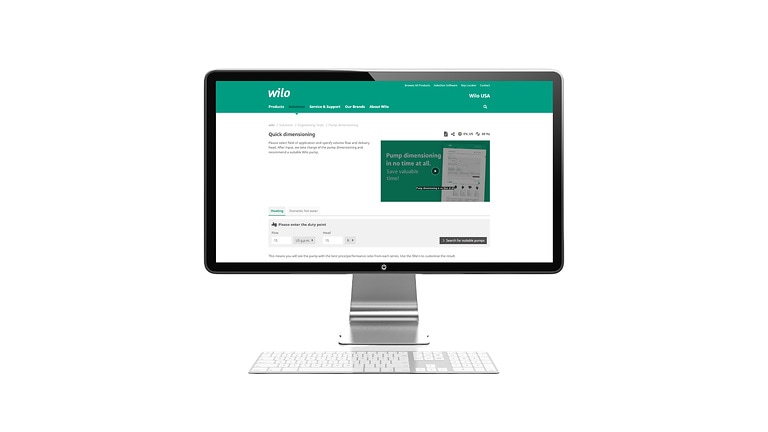

Why Wilo?

Creating

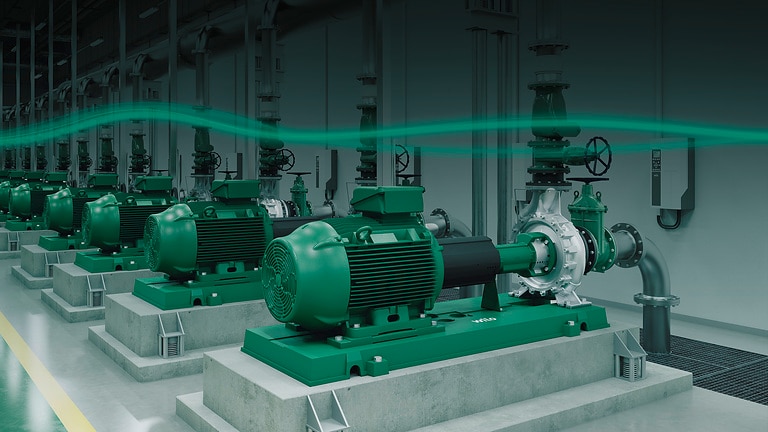

Creating Sustainable Solutions: Discover how Wilo is pioneering innovations in sustainable technologies, driving positive change for the planet and future generations.

Wilo USA News

Apr 18, 2024

Wilo USA to Host Cedar Creek Classic Bike Race

Apr 16, 2024

View our Wilo USA Q2 Newsletter 2024

Apr 15, 2024

New Wilo-CO MVI Pressure Boosting Systems